Posts tagged as ilkley

Worknotes, Autumn 2021 edition

8 October 2021It’s autumn. What’s been going on since I last wrote?

Teaching at UAL-CCI

I wrapped up a term of teaching a single module at UAL’s Creative Computing Institute.

Sound and Image Processing is a module about using code to generate and manipulate images, video, and sound. The explanation I use in the first week is: we’re not learning how to operate Photoshop, we’re learning how to write Photoshop.

The course worked its way up the ladder of abstraction, starting with the representation of a single coloured pixel, through to how images are just arrays of pixels (and video, similarly, just a sequence of those arrays). We covered manipulating those arrays simply - with greyscale filtering - and then more procedural methods such as greyscale dithering and convolution filters. We could then apply this approach to sound, too, starting by building a sound wave, sample-by-sample, and then looking at higher-level manipulations of that sound wave to make instruments and effects. Finally, having already looked at raster graphics, we looked at maniuplating vector-graphics in real time to produce animation, particle systems, and behaviour, culminating in implenenting Craig Reynolds’ Boids and creature-like simulation.

This was quite demanding: it was my first time teaching this material, which meant that before I could teach it to anybody else, I had to teach it to myself in enough depth to be confident tackling questions beyond the core material, and to be able to explain and clarify those basics. Perhaps that’s a lack of confidence showing - a kind of perfectionism as a way of hedging against coming up blank - but as the term went on, I relaxed into it, and found a good balance between preparation, delivery, and the collaborative process of teaching and learning.

And, of course, it was almost all taught entirely remotely. The students did admirably given that awkward restriction - some of them may only have been coding for a single term prior - and they delivered a great range of work in their portfolios. I’ve said yes to teaching the course again next year; whilst I greatly enjoy my commercial work, teaching aligns strongly with my values, and it’s a rewarding way to spend a small amount of time each week.

Ilkley

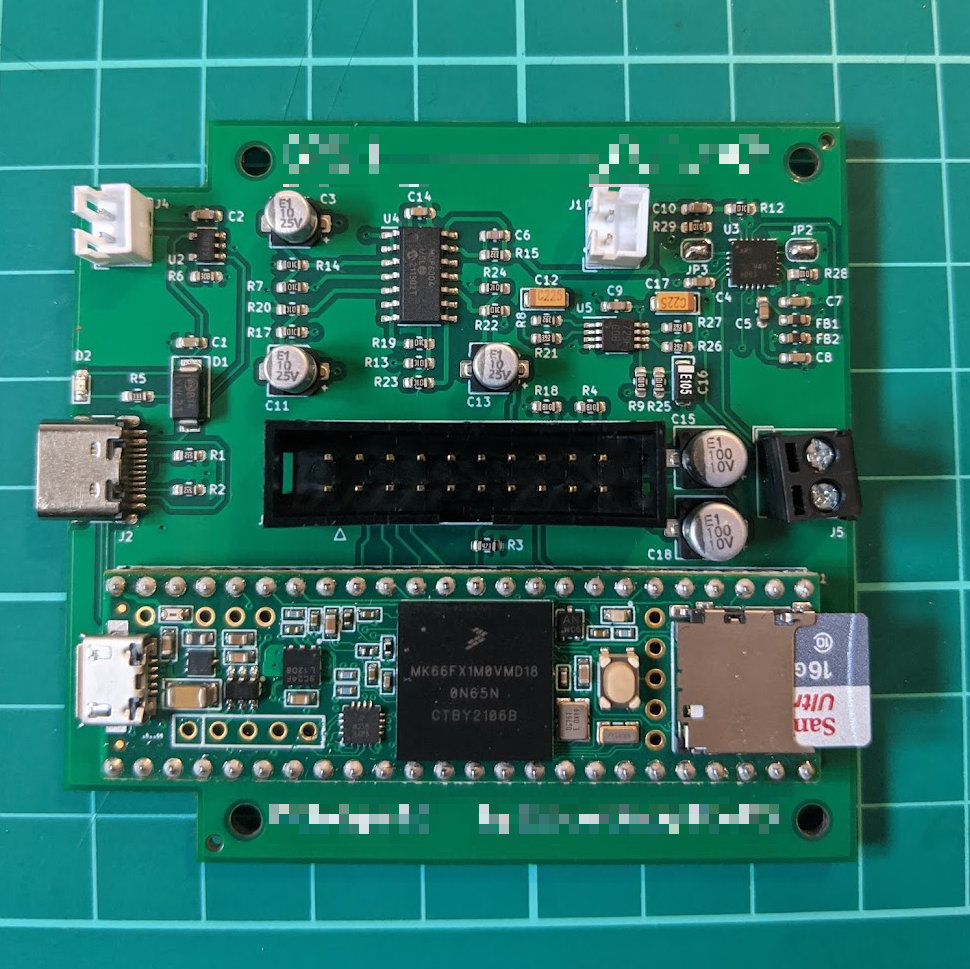

The Ilkley revision B 'brain' board, with a Teensy 3.6 attached. Ilkley has continued to run on for the spring and summer. Last I wrote, I’d just received the first Ilkley prototype board. Six months later, there have now been several more prototypes - three versions of the ‘brain’ board, and two of the upper control board. The second brain revision is the one we’re sticking with for now - the third was a misfire, and really, a reach beyond the needs of the project. By contrast, the control board was fine first time; the second version of was primarily about fitting the components in an enclosure better.

The firmware has been more stable, largely being fine out of the gate. The ongoing work was primarily about finesse, rather than wholesale replacement, so I’m pleased with that.

As I write, I’ve just packaged up five prototypes to send to Matt in New York, which wraps up the end of this phase of my work on the project. The device works end-to-end, and is ready to be played with by test users. I look forward to hearing about his results.

Wrekin

In the summer I began a new piece of work that we’ll call Wrekin, working with a very early-stage startup on building a functioning “experience prototype” to validate their product idea with real users.

This was very much a prototype in the mould described in Props and Prototypes. Some of the prototype had to be 100% working, as we wanted to evaluate certain ideas in a real implementation, to see if the technology was up to scratch, and if users liked it. One other key idea was, though core to the product, largely proven: a ‘known known’. Wwe could get away - for now - with a “stunt double” version of the idea. And then a few more pieces of the prototype were, whilst functioning, only for the experience test; they’d be thrown away in due course.

Over the course of a couple of 2-3 week phases, I built out a feasibility study, that then turned into a deployed prototype, and shipped that to the client for them to test. It’s been a fun project - some interesting boundaries of what you can do with realtime video and WebRTC - and I’ve continued to work with the client on planning future technology strategy, and, if all comes to plan, turning the experience prototype into an end-to-end one that demonstrates all pieces of the puzzle.

It’s also been a project where work on features and design concepts has directly informed future strategy. Not just thinking about what’s possible, or what is desirable, but also understanding the value of build-versus-buy for certain functionality, and for starting to explore the “what-ifs” - the unknown unknowns - that emerged as we work.

I’m continuing to advise the Wrekin team, and may be working with them a little more in the coming months.

Lowfell

Finally, Lowfell. this is another hardware project: a commission for a custom MIDI controller for an LA-based media composer, who works in film, games, and TV.

The controller itself has few features. A few people I’ve shown it to were a little underwhelmed! But the brief for the project was never about complexity.

What client wanted, really, was an axe - a “daily driver”. Something sturdy, beautiful, and not drowning in features: that just did what they need it. They were going to be looking at this thing every day, for eight or more hours a day. They didn’t need RGB lights or tons of features they weren’t going to use; just the things they did want, in an elegant and suitably-sized unit. It’s the same reason we spend a lot on a chair, or a monitor, or an expensive keyboard (or on good tools, or good shoes): you use them a lot, and it’s worth investing.

Also, they didn’t want just one: they wanted one for each setup in their studio space, making it easy to move between workstations and to keep going.

The project began slowly. We did lots of conversation just exploring the idea, and I sent some paper mockups as PDFs over email to give the client a feel for what the size of the unit would be. Once we were happy with the unit, I built a first version, with fully working electronics, and a prototype enclosure that used PCB substrate - coated fiberglass - for the panels, with the sides of the case produced on my 3D printer.

This was enough for us to evaluate functionality and features. I made sure it was trivial to update the firmware on the unit, so I could send over fixes as necessary. (In this case, because we’re using the UF2 bootloader, updating the firmware just requires holding a button on as the controller is connected; this mounts a disk on your computer desktop, to which a new firmware file can be dragged).

Whilst the client evaluated the project, I started work on final casings: using higher-quality printed nylon for the sides, and moving to bead-blasted anodized aluminium for the upper and lower panels. The result is weighty, minimal, and beautiful, and I’m looking forward to sharing more when the project is complete.

Wrekin was my main focus this summer. Ilkley and Lowfell wrapped around it quite well: the rhythm of hardware is bursty, with prototypes and design work alternating with the weeks of waiting for fabrication to come back to me with the things I can’t make myself.

What there’s not been a lot of, of course, is writing. It has fallen out of my process a little. Not deliberately; perhaps just as a byproduct of The Times, coupled with several products that were either challenging to share news on in progress, or in the case of ones with NDAs, impossible.

But: a decent six months. Up next is, I hope, shipping a final version of Lowfell, some more software development for Wrekin, and a potential small new web-based media project on the horizon. I’m on the lookout for future projects, though, and always enjoy catching up or meeting new people, so if you think you’ve got a project suited to the skills or processes I write about here, do drop me a line.

Worknotes for March 2021: 'What is this prototype for?'

23 March 2021Last week I sent all the files necessary to build the first draft at my Ilkley prototype to China. That means the plotting files to make the circuit boards, the list of all the components on them, the positions of all the components. The factory’s going to make the circuit boards and attach most of the components for me.

This is good, because many of the components are tiny.

The Ilkley prototype is on two boards: a ‘brain’ board that contains the microcontroller and almost all the electronics, and a separate ‘control’ board that is just some IO and inputs - knobs, buttons. I am focusing on the brain right now: its “revision A” board is the right size and shape to go in our housing; the current prototype of the control board is just designed to sit on my desk.

About six hours after I sent it all off, I got an email: I’d designed around the wrong sized part. (I’d picked a 3mmx3mm QFN part instead of a 4mm square part, because that’s what had been auto-selected by the component library). This meant they couldn’t place the part on the board: it wouldn’t fit.

“Should we ignore the part and go ahead with assembly?“

At this point blood rushes to my head. That part is one of the reasons I’m not building it myself: it’s not really possibly to attach with a soldering iron, and I don’t have a better tool available at home. So maybe I should quickly redesign around the right part? I hammered out a new design in Kicad.

But now I’d have to send new files, new placements over, and probably start the order again. This was going to add delays, might not even be accepted by the fabricator, and so on.

Deep breath.

At this point, I took a step back, and had a cup of tea.

Over said tea, I made myself answer the question: what was this prototype for?

Was it only to test the functionality of that single chip that couldn’t be placed? The answer, of course, was no. There were lots of things it evaluated, and lots of things that could still be evaluated:

- many other sub-circuits - notably, a battery charger, a second amplifier, a mixer

- the integration with the ‘control board’ and the feasibility of my ribbon-cable prototype

- how several parts ended up being fitted, which the fabricator has not used for me before

- the fit/finish inside our final enclosure

- not to mention whether I’d made any other mistakes on the board.

So far on Ilkley, we have been lucky: every single first revision of our hardware’s worked. This doesn’t mean we’re brilliant at everything; it means nothing more than that we’re in credit with the gods of hardware. Something will go wrong at some point - that’s what

revision Bis for. All that had happened was I’d hit my first big snag.Prototypes aren’t about answering every question, but they’re rarely also about answering one. I usually teach people to scope them by being able to answer the question what is being prototyped here? - the goal being to understand what’s in scope and what is not. Temporarily, in the panic of a 4am email from China, I forgot to answer that question myself. It was good to be reminded how many variables were at play in that Revision A, if only to acknowledge how many things I have going on with that board.

I wrote back to the factory; ignore the part and proceed. We’d still learn a lot from the prototype, and revision B would contain, at a minimum, a new footprint for that 4mm QFN chip. I saved the hasty changes I’d made to the circuit board after the email in a new branch called

revision_b- which I’d return to working on once the final boards arrived.Worknotes - February 2021

24 February 2021It’s the middle of February, 2021. What’s going on since I last wrote, and what’s coming up next?

Wrapping up at CaptionHub

My stint at CaptionHub got extended a little, and I finally wrapped in the middle of February, last week. Everything went as well as I could have hoped on the overhaul of some fundamental parts of the codebase that I was working on.

I’m pleased with the decisions we made. It was good to review all the work with the team and agree that, yes, those decisions we took our time over and drew so many diagrams of were sensible ones, and it had been worth investing the time at the point in the process. We added more complexity in one location, but managed to remove it from several others, and I enjoyed the points where code became easier to re-use simply because we had standardised an interface.

A pleasure to be back writing Ruby, too; not just for its familiarity, but for just how it is constantly such an expressive language to work in and to write. And, of course, a pleasure to work with such a sharp and thoughtful development team.

Working with Extraordinary Facility

I started working with Matt at Extraordinary Facility around the end of January. Let’s call this project Ilkley for now. It’s years since I worked with Matt at BERG, and I was excited for the opportunity to work with him again. I enjoy his eye, taste, and process as a designer so much. You should definitely check out his recently published Seeing CO2 prototype for an example of his approach.

Ilkley is a physical product prototype. I’m taking a prototype that existed between hardware and computer software, and shrinking it into a dedicated box: porting all the code to run on a microcontroller, building the user interface, adding necessary extra hardware to make it entirely standalone… and then designing custom circuit boards to fit into an enclosure. That means: firmware, a bit of EE, some CAD, and then iterating software to get it feeling right. Leaping back and forth between the digital and physical, and code, electronics, and atoms; from pens and paper to alt-tabbing between code editors, KiCad, and Fusion 360. It’s been highly enjoyable so far.

I’ve appreciated the way Matt is laser-focused on the outcomes he’s looking for. The existing prototypes were the design work; this phase is entirely about bringing that design to life. Implementation, feasibility, and building a roadmap for the future. Until he can get more people to use it, it’s not worth us spending time altering anything else. We still go off on diversions and discussions, of course, as we chat things over, but they’ll get gently parked before they jump their place in the queue. It’s great to still have those discussions, though!

Our first tranche of work investigated whether what Matt hoped for was possible. The answer was an emphatic yes, and by the end of it, we’d gone from a large breadboard and tangle of jumper wires on my desk to a small, custom “bench prototype” PCB. Nothing that could fit into a box yet, but something I could reliably send Matt (in New York) to evaluate and test. (Which in itself helped me prototype the answers to “_how do we best ship prototypes across the Atlantic_”).

I also could then start prototyping other submodule circuits on breadboards, experimenting with them whilst not worrying about the main electronics, which were ‘frozen’ thanks to having a fixed design.

One top tip from this process: something that helped enormously was continuously maintaining an up-to-date schematic of the breadboard prototype as I worked on it. As I built the tangly prototype on my workbench, I also drew it up in KiCad, altering it whenever wiring changed, or resistor values were altered. The tangle got more complex as time went on, but this didn’t matter, because there was always a map of it available in the ECAD tool. When we were happy with the prototype I’d been demoing on video calls, it was easy to start the work to turn it into a PCB because I already had the schematic. I didn’t need to start deciphering the knot of wires; I could just put them to one side and move straight onto board layout.

I did exactly the same for the small submodules as I built them; those schematics would then be ready to use again for the first ‘full’ prototype.

Progress has been really good, and I’m going to start a second phase of work soon, to take the various sub modules and bench-sized prototype, and start turning it into an entirely self-contained object. That’s going to run over the next couple of months, I’d imagine, with some gaps to get things fabricated and pull things together.

Teaching at UAL CCI

Having wrapped at CaptionHub, and with at least one client project moving on, I’m also going to be teaching an undergraduate course at UAL’s Creative Computing Institute - the Sound and Image Processing module for students in the first year of their BSc. One afternoon a week, for the next three months.

Why teach? I’m not an academic, and don’t plan to become a full time researcher or lecturer. But I’m dovetailing a small amount of teaching around my client work over the past few years - Hyper Island, the IOC, and now this.

A few answers spring to mind.

Firstly, it’s a bit about the shape of the “industry” I work within. I’m a consultant and freelancer. How do I develop talent, or share my knowledge with others? I can’t do it with the other employees of my company of one. Sharing my knowledge with students and learners through teaching engagements is one way I can. Many of my peers who are located more within the Design community integrate teaching into part of their practice well, and whilst I often use the word ‘design’ to describe a lot of my work, ‘technology’ is also an important part of my practice - and ways of integrating teaching into technical practice is something I perhaps don’t see as much of. So I’m going to see how it goes.

Secondly, I find it a great way to cast a lens at my own practice. Nothing forces you to re-evaluate your own work, approaches, or knowledge, than having to explain or discuss ideas with others. Is it selfish to say that? I don’t think so; more just to reinforce that you can’t help but learn things yourself by going through the process of teaching.

And perhaps most importantly - I learn from all the students I teach. This is in part a reflected version of the previous point - yes, I learn by looking at my own understanding and reflecting on it… but I also learn from listening and sharing with others. Students and learners at all levels bring new perspectives, expertise, experience, and ways of understanding to the table, and I (along with the rest of the group) get to share in that with them.

All of which I value. So, an opportunity arose, to think about images and sound from first principles, and ways of exploring and explaining that. I said yes.

Which all feels like a good slate for now: prototyping design products; teaching about the landscape of code; a little slack between all that for reflection and personal development and work, which (at the end of a year that was already busy before being A Bit Much on top of it all) is much needed.

Onwards.