Posts tagged as worknotes

Worknotes: Summer 2024

18 July 2024Coming up for air.

What happened is: I lined up the Next Thing (as mentioned at the end of last quarter’s worknotes), and then it promptly proceeded to entirely consume my time and brain for the next quarter.

Which is good, from an income-and-labour perspective, but was somewhat to the detriment of the content strategy here, where I’d hoped to be able to write smaller, spikier pieces of content between the studio updates.

So a goal for this quarter: making sure I don’t let client work overwhelm the routines I’d like to establish.

What’s been going on for the past few months?

Google Research/Deepmind AIUX - prototyping and exploration

The previous Next Thing.

Just as the quarter was beginning, I lined up a short, intense prototyping project with the crew at AIUX that I’d previously worked with. They began the project within Google Research, but by mid-project had been reorganised into Google Deepmind.

This made almost no difference to our work, though it did make the “ooh” people make when you tell them who your current client is go up a semitone more than usual (before you tell them you can’t tell them anything else owing to confidentiality).

I spent a couple of months with a motley crew of internal and external folks, pulling together an interesting, full-stack working prototype. Designing interactions, poking technology to see what it feels like, working out how to communicate the new ideas that a piece of software makes possible.

I think all I can say about what we were up to is “stuff to do with vector embeddings”.

The stakeholder feedback at the end of the project was really enthusiastic, and there’s talk of further work on this brief. Very much the right project at the right time.

Creative Computing Institute - end of term

June marked the end of term at CCI, where I wrapped up my fifth year of teaching Sound and Image Processing to first year undergraduates - and which means shortly after I’ve breathed out from the end of class, I have to mark 31 portfolios. It’s a lot to get through, but I’m always surprised and delighted by the places some students will take me, and it’s those moments that keep me going as I work through reading and executing a lot of Processing.

When I tell people I’ve been marking, they often ask about the impact of ChatGPT on my results. All I can say is: yes, we are educating in the age of ChatGPT now. (Other LLMs are available; I’m using ChatGPT as shorthand for LLM chatbots you ask for answers).

We don’t have a problem with students using LLMs; they’re a tool like any other, and for students less confident in a second (or third+) language, or students newer to programming, they can be a confidence-booster. We ask students to cite them just like any other source. (I usually teach citation by suggesting you quote as little as possible, and then, if you are uncomfortable revealing the size of your quotation, perhaps that’s an indication for you to quote less.)

Despite this, I believe I had many students who used ChatGPT and didn’t cite it. You can’t prove it, but there’s a… vibe? Smell? It never feels like plagiarism or copying; it’s more like a number of students all sharing the same tutor, whose personal style and predilections keeps appearing in their work. The programming equivalent of delvish, perhaps. (I had lots of

(int)style casting this year, for instance, which seemed like a tic given I’d never really introduced it, and Processing’s built-inint()function is probably more intuitive).But there are also thoughtful uses of these tools. I’ve had students submit entire transcripts of their conversations with ChatGPT, for instance, which has been good: they showed they had the knowledge necessary to ask meaningful questions and build on them, and showed how they refined their own knowledge in the dialogue. I’ve also had students describe processes - one talked about submitting his code to ChatGPT and then asking how would you improve this? which is an interesting approach to virtual pairing/refactoring, and shows a good degree of insight - not to mention curiosity.

With marking done, I rounded out the year by going to the student festival, the end-of-year show of work. This was the second year where students I’d taught in their first undergraduate year were graduating. It was hugely enjoyable and rewarding to see how they have developed, and how they are expressing their ideas and interests in creative computation a few years down the line.

Lunar - hardware/software refinements

I’ve just kicked off a very short engagement with Lunar - some further refinements to the LED interaction tools work that we did. Some new hardware, and a revision to both firmware and browser tooling has made for a busy week back leaping between C++ and Typescript.

What’s next?

The next few months are coming into focus now. August looks a little less frantic, with some smaller projects slotting into the schedule alongside a deliberate amount of Slack, and there are rumblings of larger work in September that could keep me busy for several months.

Meanwhile there’s admin to be done, and some plates to keep spinning, as well as making sure I return to some Process Notes here. And so: onwards!

Worknotes: Spring 2024

26 March 2024A quarter has passed since the last worknotes; now’s a good time to reflect on what I’ve been up to.

Lunar Energy

Two pieces of work this quarter with the Design team at Lunar. I wrapped up the project mentioned at the end of 2023 in January, as I’d expected. A second project emerged in March, exploring generative/systemic graphic and motion design, and that wrapped that up this week. There should be things I can point at and say more about very soon.

Creative Computing Institute

It’s spring break currently - the gap between the second and third terms - at CCI. I wrapped the first half of the first year undergrad class I teach; I’m back in early April for the summer term, when we’ll be looking first at audio, and then at particle systems. I particularly enjoy the latter - it’s such a rich and fun topic to play with in code.

Work with Acts Not Facts

A small project with Matt W over at Acts Not Facts, which there’s not much to say about right now, but had some good in-room collaboration. Oh, and his AI Clock - Poem/1 - that I’d previously done some firmware work on - hit its goal on Kickstarter (and then some - 117% funded), which is excellent news, and means that will be getting into the world.

Ongoing consulting

Technical/strategy consulting with the very early-stage startup I’m advising continued; just this week I’ve been helping them get a prototype of a core concept up and running, so that they can evaluate and test it with real users.

I also had a catch-up about a games project I’d been lightly advising on; they’ve got funding, which means there’s some thinking/consulting/plotting - and maybe prototyping - to come in the next quarter.

Content strategy for this site

One of the outcomes of some recent coaching with Andrew Lovett-Baron was overhauling how I communicate a bit; trying to build up a cadence of content here again. Weeknotes served me well for so long, but they are had to maintain in fallow periods, or in long periods of NDA’d work. So they fell by the wayside a bit.

I’ve decided to try to move to a more programmed set of formats: regular-ish (eg, quarterly) Worknotes that describe recent output and projects; Process Notes that talk about studio practice and process, not necessarily focused on a recent project, but as a way of demonstrating my own practice and approach; and writing about One Thing from time to time, as a way of sharing insight and critique - as well as the kinds of things that interest me as a designer/technologist.

So far: I think it’s going OK?

Spending time with peers

I’ve spent a bunch of Q1 2024 just taking time to catch up with peers and colleagues to compare notes on… this and that. That’s been, as usual, restorative. I’m writing this to remind myself - and you, reader - that it’s worth expending the effort on. As a sole practitioner, it’s worth spending time maintaining the collaborative/conversational/social aspects of work that just aren’t there when you’re on your own most days. Q1 was a good period to recharge in.

What’s on the horizon for the coming months: wrapping this term of teaching; beginning consulting on the above games project; some ongoing hardware prototyping/exploration; lining up the Next Thing. Onwards.

Recent strategy/consultancy work

18 August 2023In the past couple of years I mentioned working on an early-stage startup project I codenamed Wrekin (see relevant blogposts) - in part because it hadn’t launched out of stealth. Since then lots has moved on, not least the launch of the product as Castrooms.

Castrooms brings the energy of a crowd to music livestreaming. It’s a streaming platform designed first and foremost for music - for both performers and fans. Audience members watch streams with their camera on: performers have a crowd to perform and react to, and fans can go to shows and performances with their friends, the live music experience of “small groups as part of a bigger group”.

The product has taken off since I worked on those early prototypes. Back in 2021, I built just enough to help them validate the idea, work out what was feasible with available technology, and understand what would need to come next.

Since then, they’ve fleshed out the offering, developed the branding, greatly expanded the technical platform, run many test parties, forged relationships with DJs and musicians, and raised more funding. Since I last wrote there’s been a little more advisory and consulting work with them. It’s been exciting to see the product take off, and hear the team tell me about their growth and successes.

I spent some time this between 2022 and 2023 working with a very early-stage health startup, delivering a few strategy workshops.

This consultancy work began with a request for a single day’s workshop. I immediately suggested this would better be spent as two half days. Anyone who’s workshopped knows the “4pm lull” well - but I also believe that a break between the workshops leads to more effective outcomes. Yes, participants get a break, and can come back refreshed - but it also forms a neat point to do any ‘homework’ required. Sometimes, doing some independent research, confirming some facts, or thinking through ideas with other people outside the process, is what’s needed to make any decisions or move things forward. That’s better done outside the workshop space. We returned to the second half of the workshop much more focused, and with ideas that emerged in the first half already fleshed-out and ready for deeper discussion.

A follow-up workshop some time after the initial engagement was similarly productive. It was also rewarding - it was great to see how much the product had developed in the months that had passed, how many ideas born in the first workshop were being validated or developed in the world, with customers, and how the offering was being focused.

Summer 2023: what's on the slate?

1 August 2023What’s been going on in the studio this summer?

UAL Creative Computing Institute

I finished another term of teaching at CCI: as usual, teaching the first year BSc Creative Computing students about Sound and Image Processing - an introduction to implementing audio and graphics in code. That means pixel arrays, dithering, audio buffers, unit generators, building up to particle systems and flocking - all with a focus on the creative application of these topics. It was great to see where the students had got to in their final portfolios - some lovely and surprising work in there, as always.

A reminder: why do I teach alongside consulting and development work? I have no employees, and so this is my way of sharing back my knowledge and developing new talent - as a practitioner-teacher, and as someone who can share expertise from within industry back to students looking to break into it.

I value “education” as an ideal, and so spending about half a day a week, around client work, for a few months, to educate and share knowledge feels like a reasonable use of my time. It’s also good to practice the teaching/educating muscle: there’s always new stuff to learn, especially in a classroom environment, that feeds into other workshop and collaboration spaces.

AI Clock P2

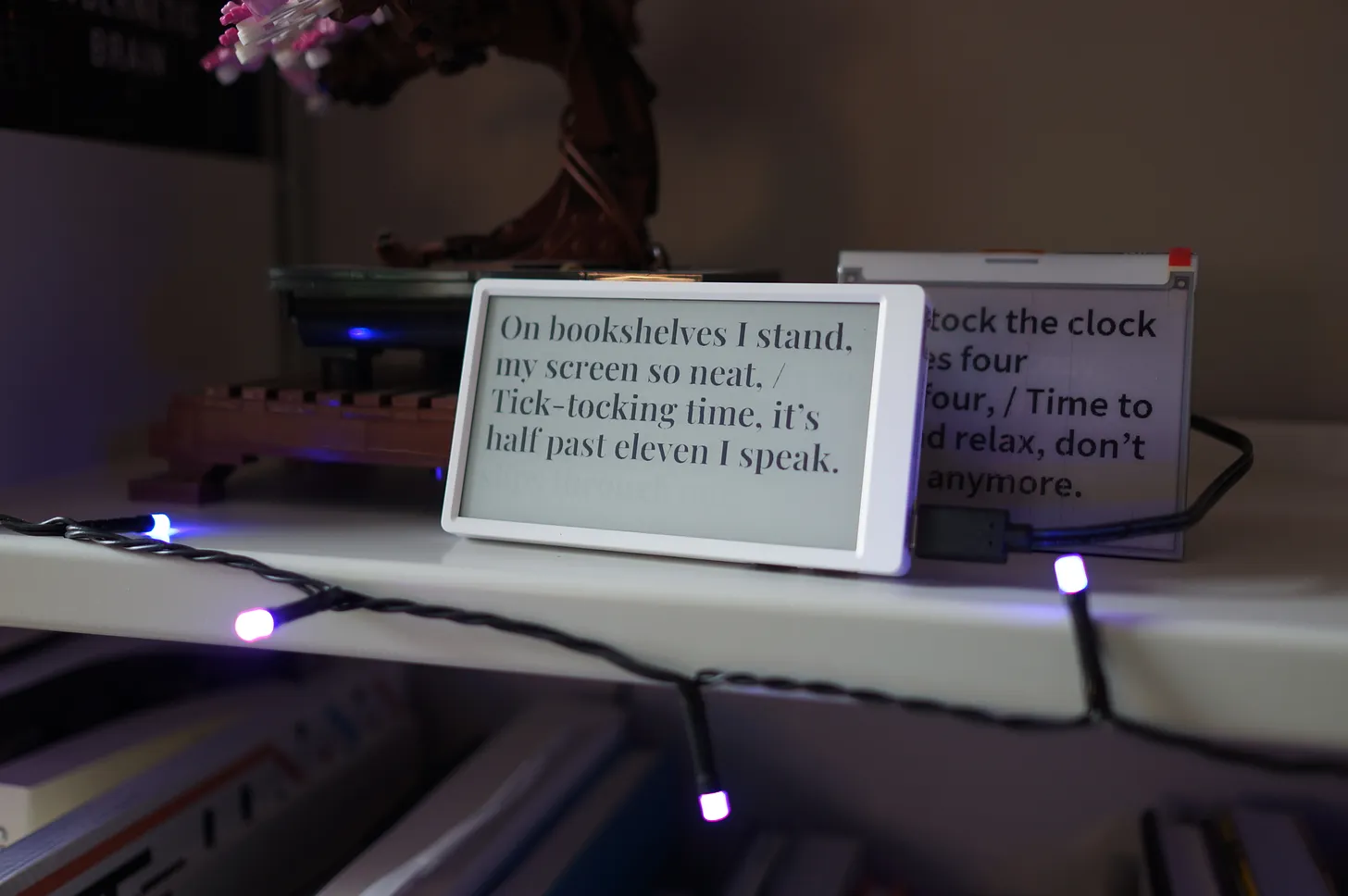

Matt's photo of P2 on his shelf I spent a short while working with Matt Webb on “P2” - prototype 2 - of his AI Clock. He’s written more about this prototype over at the newsletter for the project - including his route to getting the product into the world.

This prototype involved evaluating a few different e-ink screen modules according to Matt’s goals for the project, and creating a first pass of his interaction design in embedded code. I built out the critical paths he’d designed for connecting and configuring the clock, as well as integrating it with his new API service. The prototype established feasibility of the design and, during its development, informed the second version of the overall architecture.

Since I’ve handed over the code, he’s continued to build on top of it. I find this part of handover satisfying: nothing is worth than handing over code and it sitting, going stale, or unmaintained. By contrast, when someone can take what you’ve done and spin it up easily, start working with it, and extending it - that feels like part of a contracting/consulting job well done: not just doing the initial task, but making a foundation for others to build on. Some of that work is code, some of it’s documentation, and some of it’s collaboration, and it’s something I work towards on all my client engagements.

Lunar Energy

I’ve been working on a small project with Lunar Energy. The design team were looking to prototype a specific hardware interaction on the actual hardware involved. I’ve been making hardware and software to enable the designers to work with the real materials in a rapid fashion - and in a way that they can easily share with technical and product colleagues.

It’s been a great example of engineering in the service of design, and of the kind of collaborative toolmaking work I both enjoy and am particularly effective at. I’ve been jumping back and forth between browser and hardware, Javascript and embedded C++, and I think we’ve got to a really good place. I can’t wait to share a case study.

Promising Trouble

Finally, I’ve started a small consultancy gig with Promising Trouble on one of their programmes, spread over a few days this summer, and then a few more towards the winter. My job here is being a technological sounding board and trusted advisor, to help join the team join some dots on a project exploring a technological prototype to address societal issues. A nice consultancy project to sit alongside the nitty-gritty of the Lunar work.

and…?

And what else? I have capacity from early August onwards, so if you’d like to talk about opportunities for collaboration or work, now is a great time to get in touch. What shape of opportunities? Right now, my sweet spots are:

- invention and problem-solving: answering the questions what if? or could we even?; many of my most successful and impactful projects have begun by exploring the possible, and then building the probable.

- “engineering for design” - being a software developer in the service of design, or vice versa; the technical detail of platforms, APIs, or hardware is part of what we design for now, and recent work for companies like Google AIUX and Lunar has involved straddling both worlds, letting one inform the other, working in tight cross-functional teams to build and explore that space, and ultimately communicating all of this to stakeholders.

- projects that blend the digital and physical. I’ve been working on increasing numbers of projects that straddle hardware, firmware, and desktop or browser software, and the interactions that connect all of them.

- technology strategy; that might be writing/thinking/collaborating, or building/exploring, or first one, then the other; I’ve recently done this with a few early-stage founders and companies.

- focused technical projects, whether greenfield or a companion to existing work - that might be adding or integrating a significant feature, or building a standalone tool. I tend to work on the Web, in Ruby, Typescript and Javascript (as well as markup/CSS, obviously). I like relational data models, HTTP, and the interesting edges of browsers.

- and in all of the above: thinking through making, informing the work through prototypes and final product builds.

You can email me here if any of that sounds relevant. And now, back to the desk and workbench!

Spring 2022 Worknotes

20 April 2022What happened was: I meant to write about the end of 2021 before a big project in 2022 kicked off. And instead, 2022 came around, the project kicked off hard and whoosh it’s now the Spring.

I have been quiet here, but busy at work. And so, here we are.

What’s been going on?

Wrekin wrapped up in the autumn, as expected. I completed my final pieces of documentation, and handed them over. Recently, I’ve been doing a small amount of handover and advisory work with their new lead developer as they push through the next phase of the project. I’m excited to see where they’ll take it.

The small media project I mentioned last time came to fruition. Codenamed Hergest, it was a proof-of-concept to explore if a product idea was achievable - and feasible - within a web browser. Rather than prototype the whole product, I focused on the single most important part of the experience - which was also the single most complex part of the product, and the make-or-break for if the product was feasible. We got to a point where it looked like it would be possible, and I could frame what it’d need to take forward - to “paint the rest of the owl“, as I described it to the client.

Hergest covered a fun technology stack: an app-like UI in the browser, using a reactive web framework; on-demand audio rendering using Google Cloud Run; loading media from disk without sending it across the network thanks to the File API; and working with Tone.js for audio functionality in the browser. It’s remarkable what you can do in the browser these days, especially in contexts where such rich behaviour is appropriate. In a few weeks of prototyping we got to an end-to-end test that could be evaluated with users, to understand demand and needs without spending any more than necessary.

Lowfell has slipped a little, which is on me: there was some issues with UPS shipping, and then pre-existing commitments managed to steal a lot of my energy. I’m hoping to resolve this in the coming weeks, but I did at least get a second prototype shipped and a 1.0 firmware built and signed off.

There was more teaching. I returned to be industry lead for the Hyper Island part-time MA, and spent some good days with an international crew delivering some lectures and coaching them on their briefs - this time, a particularly interesting brief delivered by Springer Nature. The students really got stuck in to the world of scientific publishing; a shame we were still delivering remotely, but not much else could be done there. I also am teaching at CCI again, delivering Sound and Image Processing for first year Creative Computing undergrads for one morning a week, through to the summer.

Finally, in Q1 I kicked off a three month project working with Normally. A team of three of us worked on a challenging and intense public sector brief. Gathering data, performing interviews, sketching, and prototyping; we spent 12 busy weeks exploring and thinking, and I was personally really pleased where the final end-to-end prototype we shipped - as well as the accompanying thought and strategy - ended up. It was great working with Ivo and Sara, as well as spending time in the wider Normally studio, and perhaps our paths will cross again. It was a great start to the year, but pretty intense, and so I didn’t have much time outside it for reflection.

What’s up next?

Two existing projects need wrapping: firstly, finishing up term at CCI and marking some student portfolios, and also wrapping up Lowfell.

Secondly, I’m going to spend the summer working with the same crew inside Google Research that I worked on Easington with, on a interesting internal web project. Not a lot to be said there, but it’ll keep me busy until the autumn, and I’m looking forward to working with that gang again.

And so, as ever: onwards.

Worknotes, Autumn 2021 edition

8 October 2021It’s autumn. What’s been going on since I last wrote?

Teaching at UAL-CCI

I wrapped up a term of teaching a single module at UAL’s Creative Computing Institute.

Sound and Image Processing is a module about using code to generate and manipulate images, video, and sound. The explanation I use in the first week is: we’re not learning how to operate Photoshop, we’re learning how to write Photoshop.

The course worked its way up the ladder of abstraction, starting with the representation of a single coloured pixel, through to how images are just arrays of pixels (and video, similarly, just a sequence of those arrays). We covered manipulating those arrays simply - with greyscale filtering - and then more procedural methods such as greyscale dithering and convolution filters. We could then apply this approach to sound, too, starting by building a sound wave, sample-by-sample, and then looking at higher-level manipulations of that sound wave to make instruments and effects. Finally, having already looked at raster graphics, we looked at maniuplating vector-graphics in real time to produce animation, particle systems, and behaviour, culminating in implenenting Craig Reynolds’ Boids and creature-like simulation.

This was quite demanding: it was my first time teaching this material, which meant that before I could teach it to anybody else, I had to teach it to myself in enough depth to be confident tackling questions beyond the core material, and to be able to explain and clarify those basics. Perhaps that’s a lack of confidence showing - a kind of perfectionism as a way of hedging against coming up blank - but as the term went on, I relaxed into it, and found a good balance between preparation, delivery, and the collaborative process of teaching and learning.

And, of course, it was almost all taught entirely remotely. The students did admirably given that awkward restriction - some of them may only have been coding for a single term prior - and they delivered a great range of work in their portfolios. I’ve said yes to teaching the course again next year; whilst I greatly enjoy my commercial work, teaching aligns strongly with my values, and it’s a rewarding way to spend a small amount of time each week.

Ilkley

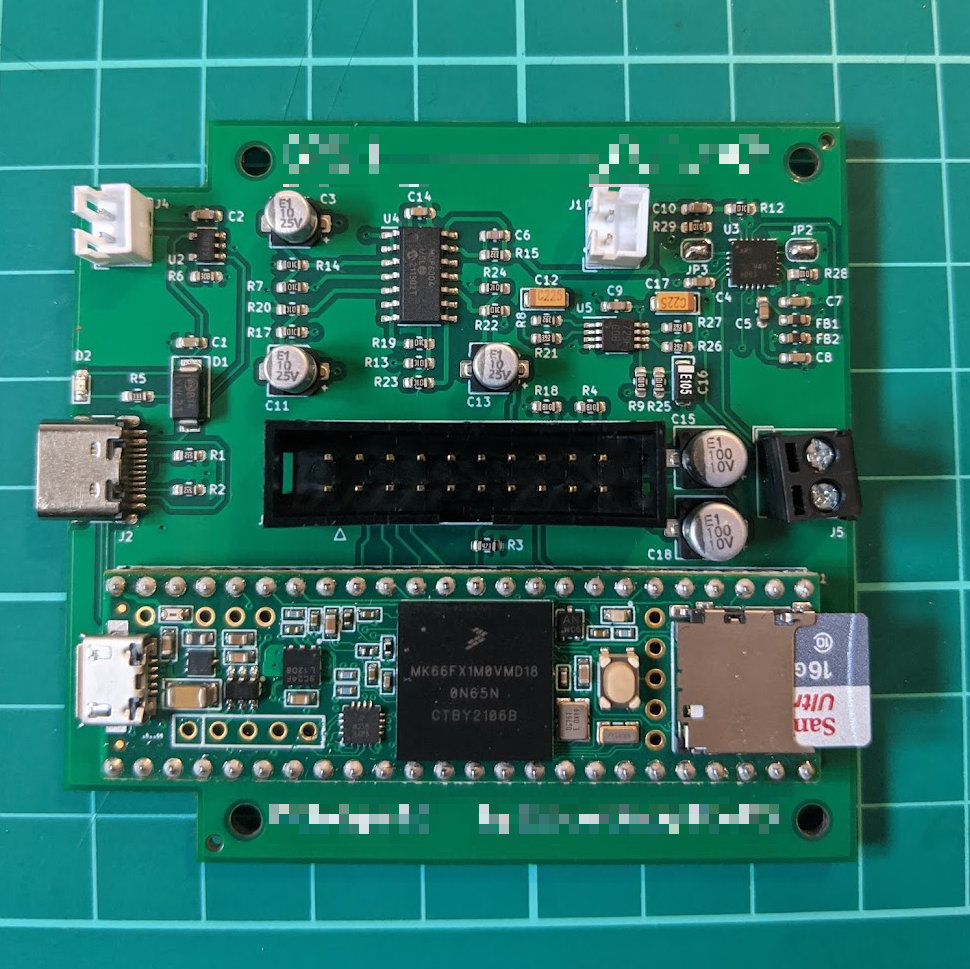

The Ilkley revision B 'brain' board, with a Teensy 3.6 attached. Ilkley has continued to run on for the spring and summer. Last I wrote, I’d just received the first Ilkley prototype board. Six months later, there have now been several more prototypes - three versions of the ‘brain’ board, and two of the upper control board. The second brain revision is the one we’re sticking with for now - the third was a misfire, and really, a reach beyond the needs of the project. By contrast, the control board was fine first time; the second version of was primarily about fitting the components in an enclosure better.

The firmware has been more stable, largely being fine out of the gate. The ongoing work was primarily about finesse, rather than wholesale replacement, so I’m pleased with that.

As I write, I’ve just packaged up five prototypes to send to Matt in New York, which wraps up the end of this phase of my work on the project. The device works end-to-end, and is ready to be played with by test users. I look forward to hearing about his results.

Wrekin

In the summer I began a new piece of work that we’ll call Wrekin, working with a very early-stage startup on building a functioning “experience prototype” to validate their product idea with real users.

This was very much a prototype in the mould described in Props and Prototypes. Some of the prototype had to be 100% working, as we wanted to evaluate certain ideas in a real implementation, to see if the technology was up to scratch, and if users liked it. One other key idea was, though core to the product, largely proven: a ‘known known’. Wwe could get away - for now - with a “stunt double” version of the idea. And then a few more pieces of the prototype were, whilst functioning, only for the experience test; they’d be thrown away in due course.

Over the course of a couple of 2-3 week phases, I built out a feasibility study, that then turned into a deployed prototype, and shipped that to the client for them to test. It’s been a fun project - some interesting boundaries of what you can do with realtime video and WebRTC - and I’ve continued to work with the client on planning future technology strategy, and, if all comes to plan, turning the experience prototype into an end-to-end one that demonstrates all pieces of the puzzle.

It’s also been a project where work on features and design concepts has directly informed future strategy. Not just thinking about what’s possible, or what is desirable, but also understanding the value of build-versus-buy for certain functionality, and for starting to explore the “what-ifs” - the unknown unknowns - that emerged as we work.

I’m continuing to advise the Wrekin team, and may be working with them a little more in the coming months.

Lowfell

Finally, Lowfell. this is another hardware project: a commission for a custom MIDI controller for an LA-based media composer, who works in film, games, and TV.

The controller itself has few features. A few people I’ve shown it to were a little underwhelmed! But the brief for the project was never about complexity.

What client wanted, really, was an axe - a “daily driver”. Something sturdy, beautiful, and not drowning in features: that just did what they need it. They were going to be looking at this thing every day, for eight or more hours a day. They didn’t need RGB lights or tons of features they weren’t going to use; just the things they did want, in an elegant and suitably-sized unit. It’s the same reason we spend a lot on a chair, or a monitor, or an expensive keyboard (or on good tools, or good shoes): you use them a lot, and it’s worth investing.

Also, they didn’t want just one: they wanted one for each setup in their studio space, making it easy to move between workstations and to keep going.

The project began slowly. We did lots of conversation just exploring the idea, and I sent some paper mockups as PDFs over email to give the client a feel for what the size of the unit would be. Once we were happy with the unit, I built a first version, with fully working electronics, and a prototype enclosure that used PCB substrate - coated fiberglass - for the panels, with the sides of the case produced on my 3D printer.

This was enough for us to evaluate functionality and features. I made sure it was trivial to update the firmware on the unit, so I could send over fixes as necessary. (In this case, because we’re using the UF2 bootloader, updating the firmware just requires holding a button on as the controller is connected; this mounts a disk on your computer desktop, to which a new firmware file can be dragged).

Whilst the client evaluated the project, I started work on final casings: using higher-quality printed nylon for the sides, and moving to bead-blasted anodized aluminium for the upper and lower panels. The result is weighty, minimal, and beautiful, and I’m looking forward to sharing more when the project is complete.

Wrekin was my main focus this summer. Ilkley and Lowfell wrapped around it quite well: the rhythm of hardware is bursty, with prototypes and design work alternating with the weeks of waiting for fabrication to come back to me with the things I can’t make myself.

What there’s not been a lot of, of course, is writing. It has fallen out of my process a little. Not deliberately; perhaps just as a byproduct of The Times, coupled with several products that were either challenging to share news on in progress, or in the case of ones with NDAs, impossible.

But: a decent six months. Up next is, I hope, shipping a final version of Lowfell, some more software development for Wrekin, and a potential small new web-based media project on the horizon. I’m on the lookout for future projects, though, and always enjoy catching up or meeting new people, so if you think you’ve got a project suited to the skills or processes I write about here, do drop me a line.

Worknotes for March 2021: 'What is this prototype for?'

23 March 2021Last week I sent all the files necessary to build the first draft at my Ilkley prototype to China. That means the plotting files to make the circuit boards, the list of all the components on them, the positions of all the components. The factory’s going to make the circuit boards and attach most of the components for me.

This is good, because many of the components are tiny.

The Ilkley prototype is on two boards: a ‘brain’ board that contains the microcontroller and almost all the electronics, and a separate ‘control’ board that is just some IO and inputs - knobs, buttons. I am focusing on the brain right now: its “revision A” board is the right size and shape to go in our housing; the current prototype of the control board is just designed to sit on my desk.

About six hours after I sent it all off, I got an email: I’d designed around the wrong sized part. (I’d picked a 3mmx3mm QFN part instead of a 4mm square part, because that’s what had been auto-selected by the component library). This meant they couldn’t place the part on the board: it wouldn’t fit.

“Should we ignore the part and go ahead with assembly?“

At this point blood rushes to my head. That part is one of the reasons I’m not building it myself: it’s not really possibly to attach with a soldering iron, and I don’t have a better tool available at home. So maybe I should quickly redesign around the right part? I hammered out a new design in Kicad.

But now I’d have to send new files, new placements over, and probably start the order again. This was going to add delays, might not even be accepted by the fabricator, and so on.

Deep breath.

At this point, I took a step back, and had a cup of tea.

Over said tea, I made myself answer the question: what was this prototype for?

Was it only to test the functionality of that single chip that couldn’t be placed? The answer, of course, was no. There were lots of things it evaluated, and lots of things that could still be evaluated:

- many other sub-circuits - notably, a battery charger, a second amplifier, a mixer

- the integration with the ‘control board’ and the feasibility of my ribbon-cable prototype

- how several parts ended up being fitted, which the fabricator has not used for me before

- the fit/finish inside our final enclosure

- not to mention whether I’d made any other mistakes on the board.

So far on Ilkley, we have been lucky: every single first revision of our hardware’s worked. This doesn’t mean we’re brilliant at everything; it means nothing more than that we’re in credit with the gods of hardware. Something will go wrong at some point - that’s what

revision Bis for. All that had happened was I’d hit my first big snag.Prototypes aren’t about answering every question, but they’re rarely also about answering one. I usually teach people to scope them by being able to answer the question what is being prototyped here? - the goal being to understand what’s in scope and what is not. Temporarily, in the panic of a 4am email from China, I forgot to answer that question myself. It was good to be reminded how many variables were at play in that Revision A, if only to acknowledge how many things I have going on with that board.

I wrote back to the factory; ignore the part and proceed. We’d still learn a lot from the prototype, and revision B would contain, at a minimum, a new footprint for that 4mm QFN chip. I saved the hasty changes I’d made to the circuit board after the email in a new branch called

revision_b- which I’d return to working on once the final boards arrived.Weeks 180, 181, and 182

24 June 2016

photo by Felicity Crawshaw from Into The Wild, the MV Works showcase

And, after all the work of a gallery show and an install, the relative calm.

Week 180 was a long week, all about Twinklr: exhibiting it at Into the Wild. I spent much of the weekend with the box, and got to see a lot of people playing with it. It was a really great experience: some good questions, some lovely feedback from musicians and peers, but also a lot of people just playing it and enjoying it for what it was. I played it a few times as small performances during the showcase: once on Friday, effectively to myself, and then in a longer demo on the Sunday afternoon, and it turned out to be as playable and dynamic as I’d hoped. It was definitely best as a controller for more involved sound-sources – but Twinklr, a monosynth and a delay pedal led to some wonderful sounds and textures.

After the show, a breather.

I have spent the weeks after getting really stuck into Selworthy again to hit a next milestone for the project. Whilst I’ve been away, our new developers have taken that ball and started running with it, and the past two weeks have seen a great amount of progress – to the point that I’m mainly thinking about tech strategy and the odd feature, rather than being sole developer.

I made good progress with Staplehill: a personal hardware project that’s spun out of Twinklr and that I’m hoping to take to Brighton Modular. I’ve ordered the 1.00 circuit boards for it, and made decent progress on the firmware; it’s very much going to come together at the last minute – the boards arrive two days before I might be showing it – but if it does, it could be very good. Regardless, it’s a project I’m going to continue to pursue.

I spent and excellent day with Alex, Peter, and many excellent folk thinking about The Good Home in a workshop, which was a great boost for the spirits: good to spend a day to think, sketch, and challenge each other (and especially so after the hecticness of gallery install).

And, as ever, a spate of meetings and coffees, some casual catch-ups, others exploratory chats with new faces. Beginning to think about what’s next in my schedule, and to look for other projects. If you think there’s something interesting to be done together – be it consultancy, workshopping, or R&D and prototyping – then do get in touch. There’s work to be done.