Posts tagged as 16nx

16nx, and the value of giving work away

27 January 2025

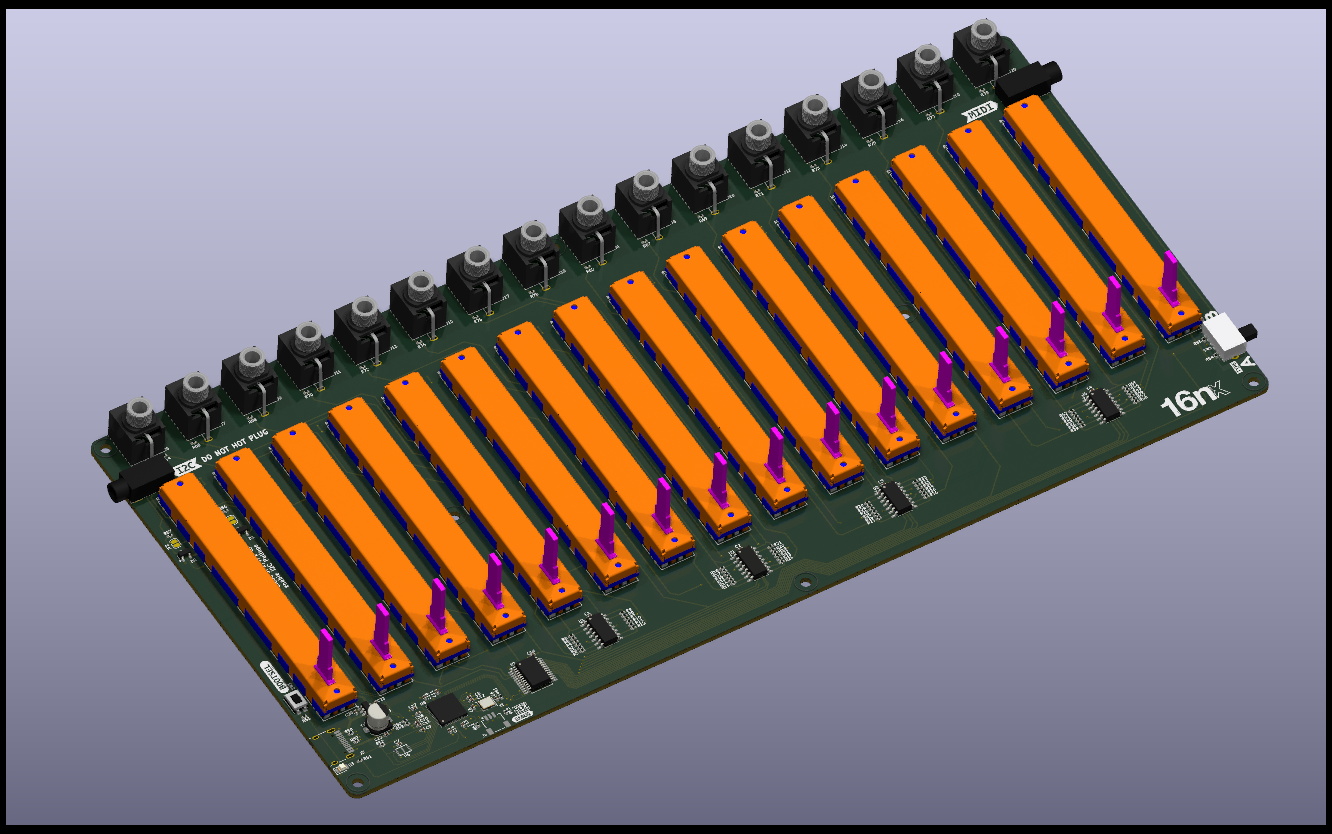

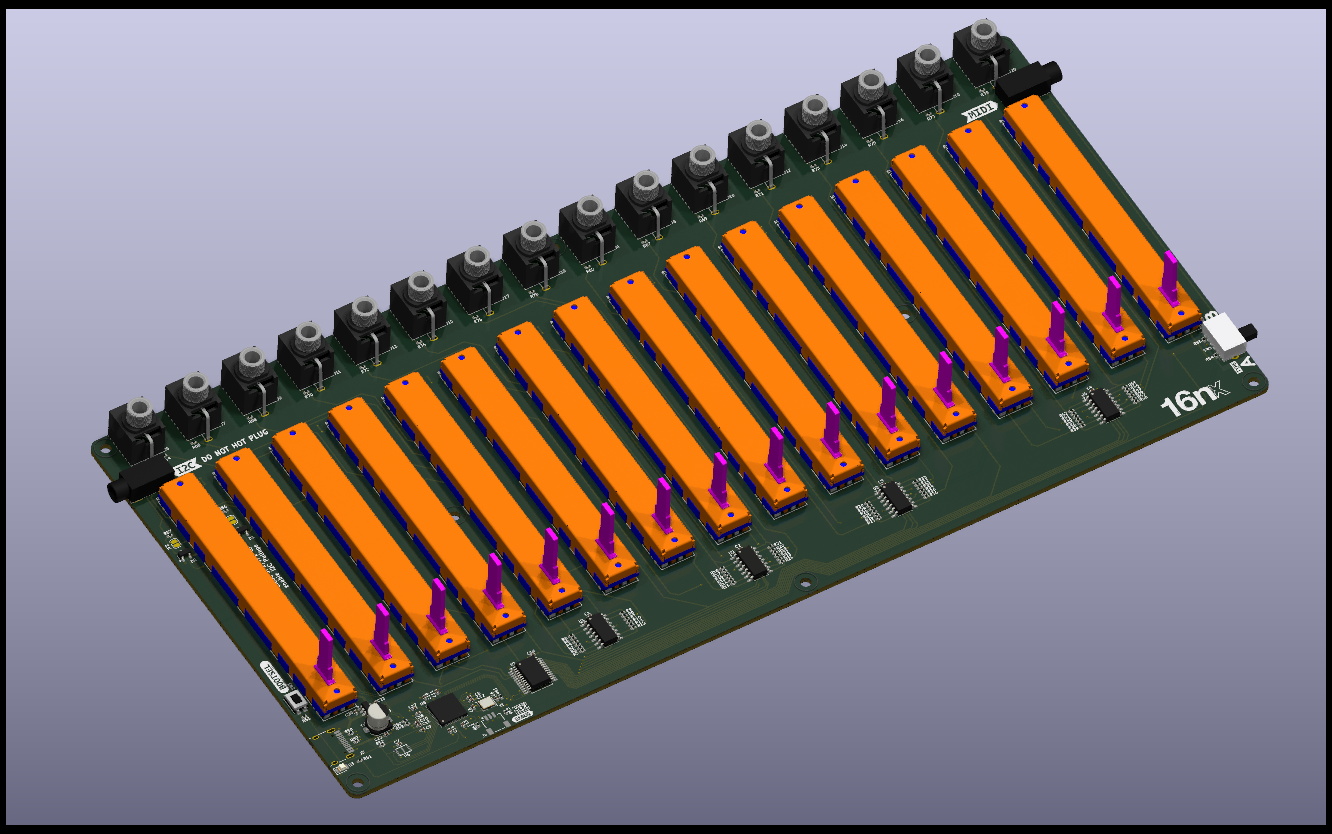

In September this year, I released a new version of the open source 16-fader MIDI controller I maintain - 16nx. This was a complete redesign of the hardware of the device, and as a result, also a completely new firmware.

Redesigning the device was in one sense, a necessity. 16n - the original faderbank - was designed around the Teensy 3.2, a microcontroller development board that had effectively become end-of-life, and was no longer available. Given that, it was impossible to make the device. If it was to be buildable again, it would need designing around a new part.

If I was going to take on the necessity of a redesign, I may as well also take up the opportunity to make changes or improvements, particularly based on what I’d learned in the years since I’d made those original designs.

I eventually released the project in September 2024 under the same open-source licences as its predecessor. As well as examining the changes in this new version, I wanted to write a little about why I’d give my work away.

The easiest approach to replacing the Teensy 3.2 would be to use its successor, the Teensy 4 - mechanically identical, it’d just take a software rewrite. But it’s vastly overpowered for the relatively simple tasks the 16n does.

And I didn’t really want a drop-in replacement. I was going to redesign the electronics anyway; I had a few goals for them:

- update the analog electronics to improve the control voltage (CV) outputs.

- get rid of the horizontal jacks on the front and rear, to make it easier to push flat against stuff. Connections would just be on the left, right, and top surface.

- change the USB connector to a more robust USB-C connector.

And if I’m redesigning the analog circuitry, maybe a more thorough redesign was in order.

Since I’d designed 16n, small-scale overseas electronics manufacture had become even easier. Assembly of boards, particularly via pick-and-place for surface mount components, was now very accessible and relatively affordable.

The original 16n was a combination of through-hole and large surface-mount components, designed for manual assembly. But in reality, even the chunky surface-mount I’d chosen to go with was fiddly for many people assembling it; the number of bugs that came down to mis-soldered resistors was quite high.

So I had an idea: perhaps all the electronics, including the microcontroller, could be on the board, and assembled in a factory. Save the manual soldering for the chunky through-hole components DIYers are happiest with, and let a pick-and-place do the rest - with cheaper, smaller components. (Tom at Music Thing Modular had already had success with this “easy-bake” approach; it turned out people don’t have to make absolutely every part of something to still get the pleasure of making something).

The project could still be open source, but for people who didn’t want to wrestle with PCBA, I could… sell these “motherboards” myself - maybe to individuals, but perhaps, more likely, to the small manufacturers who assembled faderbanks for clients.

I was attracted to this idea: the project would be easier to assemble, more robust (and less prone to assembly error by hobbyists), and I might see some ROI on the project I’d put so much effort into.

I’d base this new board around the RP2040 chip I was using for so much work now - £1 for the bare chip, a dollar or two for the rest of the required components. It’s far more powerful than low-end 8-but Arduinos, not quite as meaty as a Teensy 3.2 or 4.0, but more powerful than a Teensy LC. And its UF2 bootloader - letting users update their firmware just by copying a file on their desktop - would make end-user firmware upgrades even easier than before, a huge accessibility win.

I wrote the firmware the native C++ Pico SDK. The impact for the end-user was low - they’d get UF2s to upload - but for me was high, letting me work with a powerful toolset and a genuine debugger. I even added a mini JST connector to the board, designed to connect to the official Pico Debug Probe. It was a great help in developing the project, and felt like a good gesture to end users - you should try this approach, there’s a socket ready for you, it works with the official tools.

The trade-off to moving to Pico SDK was that the firmware would get a little less accessible for the hobbyist market. The Teensy project was written in Arduino. When I was working on that, I believed that the more people could contribute to the project, the better, so using a framework popular with makers was important. What I found out was that whilst a lot of people want to contribute bug reports or feature requests, far fewer of them wish to hack on them. No matter how much I would write, sincerely, “that sounds like a great first issue - why don’t you look at that?”, I received relatively few pull requests or forks of the firmware. So I decided to stop making choices about platforms based on what other people might do in the future, and instead choose what I thought was best.

In the end, the assembled 16nx main boards, excluding jacks, switches, and faders, would cost about a third of the equivalent parts - unassembled - for the 16n. And that’s before you consider any savings in terms of how much faster it is to assemble a 16nx - there’s no longer about 60 surface-mount chips and resistors to put on the board by hand.

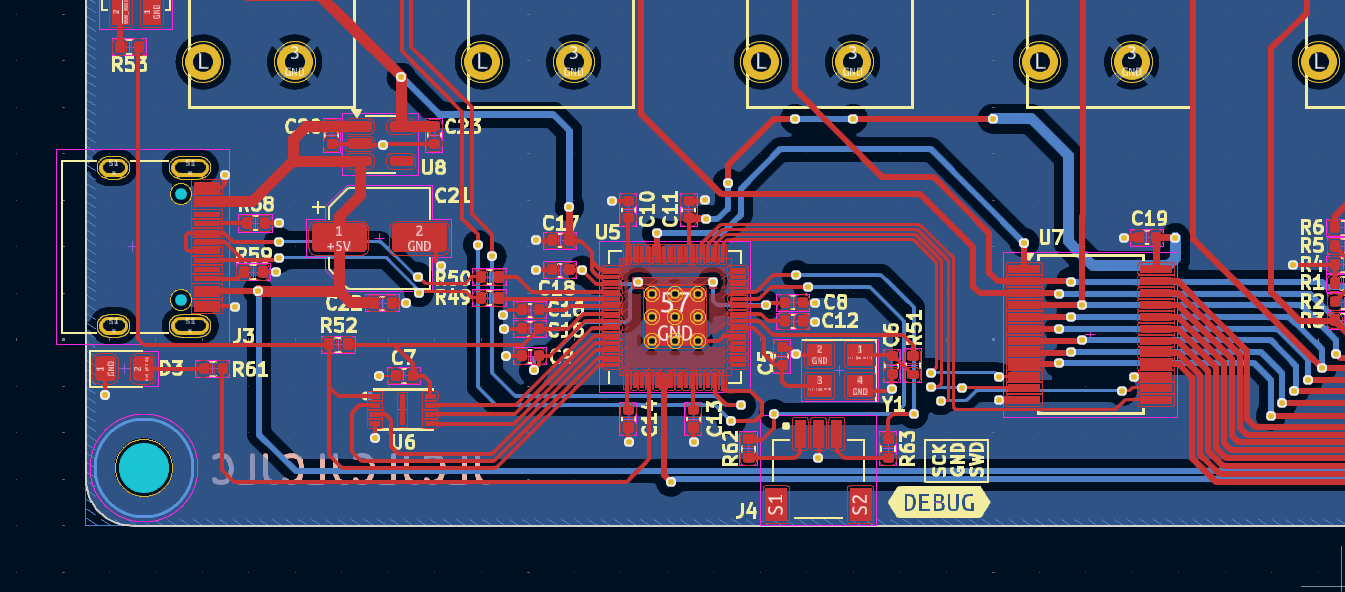

The electronics redesign took a good while. 16n had been designed inside EAGLE, which was now also end-of-life, and had been subsumed inside Fusion 360 - a good product, but hardly hobbyist-budget. An open source tool made sense for an open source project, so I designed it all inside KiCad - my ECAD tool of choice - keeping the same physical form factor. The layout took a few passes to get right, mainly down to all the routing around the MCU:

The 16nx PCB layout around the RP2040

The 16nx PCB layout around the RP2040

16n at the time was the most complex thing I’d ever routed. It’s a sign of where I’ve gone since that 16nx isn’t - just - but I’m still very proud of the electronics work on it.

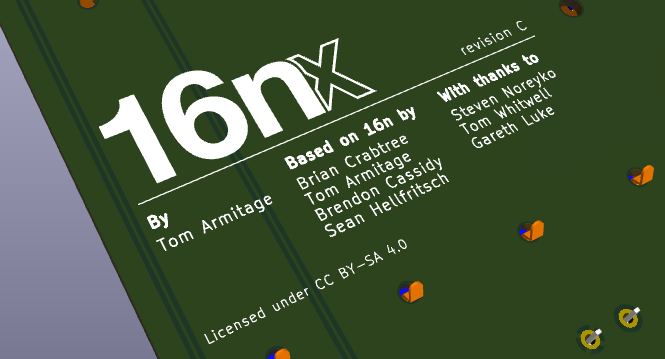

I also spent some time messing around with logos, designing things that would silkscreen nicely with a little inspiration from 90s music hardware…

A render of the board reverse

A render of the board reverse

With the firmware written, and test boards on my desk, it was time to bring it into the world.

And then… I froze.

I’d fixated on the “selling populated boards” idea as a way of generating a bit of revenue without making “full kits”, or going near sales and support of finished products. I know what I enjoy - and what I don’t - and I find support for end-users stressful (whether or not the support overhead actually materialises - the idea alone gets to me). This other approach would be less stressful than selling complete products, but still find a way for generating ROI.

But I kept getting stuck in a train of thought:

- I don’t want to do customer support at all, really. It’s bad for my brain and stress levels. Even supporting the assemblers/manufacturers I sell to might still be a pressure I wouldn’t like.

- I know enough to know I probably ought to do some form EM testing, even for a bare board. EM testing in the hobbyist industry is uneven, but do I want to take the risk of working out if I’m selling a “partial assembly” or not, and do I want to sell it on, knowing that? Conversely: will EM testing knock any margin on the head?

- This is beginning to look like a lot of work.

- What did I want out of this again?

And the answer is: I want it cheaper, and easier to make, and back in the world again for music makers, and actually, making a small amount of money probably wasn’t my highest priority.

Making a small amount of money would be more expensive, probably, than making no money.

The project was always going to be open source - it’s under an attribution licence that allows commercial derivatives. I wasn’t choosing between an open-source release, and a commercial one. But I was choosing between revenue, and not.

On my birthday, in September 2024, I published the updated 16n website, and made the first open-source release. I igave up on the idea of selling anything; easier to let people who wanted one find a way to bring it to life, just as they had done before. My main goals were met: the faderbank was back in the world, it was now possible to make one again, and it was a bit better designed, even if it did nothing new. It was quite satisfying to quell any “Gear Acquisition Syndrome” with the simple lines in the documentation:

If you already have a 16n that works: you will gain nothing by upgrading. If, however, you’re looking to acquire a faderbank in 2024+, then 16nx is your best route to do so.

There’s a long thread about it on Lines, the spiritual home of the project, and it was once again exciting to see people bringing them to life without me and enjoying the experience. That’s not nothing; I’m proud and buoyed by the response to the project.

It’s not really a “loss” in the slightest. I’ve got a great deal out of the project over the years:

- developing skills and techniques, even within tools I know well.

- facilitating new paying work: the recent Lunar hardware project wouldn’t have been doable without this, and made about as much as I’d have made trying to sell ~100 motherboards.

- building new clients: 16n led to a custom commission from a US composer that ended being a lovely project and a good working relationship.

- the value, to me, of contributing back to a community I care about of musicians and DIY makers.

When I made the decision to give it away, what I felt was relief. It turned out I was agonising over a commercial idea that wasn’t really worth enough to me, and giving that up freed me up in a lot of ways. The final release was smooth and straightforward after that.

Since launch, I’ve largely just let people get on with making them, dropping into Github or forum threads to offer some advice, and in the first week of the year, doing some point releases - upgrading the editor to Svelte 5, building a reasonably sized new feature that’s been requested and getting that ready to launch.

It continues to be a favourite project, and I’m glad that I’ve found a way to keep it going for more years to come, in a way I’m happy with.

Worknotes: Winter 2024

23 January 2025I was working up to the wire in 2024; my main client project wrapped up on December 20th. It was an intense sprint finish to the year, and since then, after some genuine rest, I’ve mainly been getting my feet back under the desk, and slowly trying to bring the shape of 2025 into focus.

What was I up to in the past six-ish months?

Google Deepmind - further prototyping / exploration

I returned to the AIUX team at Deepmind for another stint on the project we’d been working on (see: Summer 2024 Worknotes), taking us from September through to the end of the year. This was meaty, intense, and involving, but I’m pleased to where it got to.

This time, the focus was in two areas: replatforming the project onto some better foundations, and then using those new foundations to facilitate exploring some new concepts.

This went pretty well, and I got to spend some good time with Drizzle (now in a much better place than when I first used it a long while ago; rather delightful to work with) and

pgvector. Highly enjoyable joining vector-based searches onto a relational model, all in the same database.And I think that’s all I can say about that. Really good stuff.

Poem/1 - further firmware development

I continued occasionally work on the firmware development of Poem/1 with Matt Webb. The firmware was in a good place, and my work focused on formatting and fettling the rendering code, and iterating on some of the core code we’d worked on earlier in the year.

16nx

In September, I released a completely new version of the open-source MIDI controller I make. It has no new functionality. Instead, it solves the more pressing problem that you could no longer make a 16n, because the development board it was based on is no longer available. I ported everything to RP2040, and designed it around a single board with all componentry pre-assembled on it. I’ve got a case study of this coming next week, examining what I did and why, but for now, the updated 16nx site has more details on it. Another full-stack hardware project, with equal parts CAD, schematic design, layout, and C++.

Ongoing consulting

I kicked off some consulting work on a geospatial games project, currently acting as a technical advisor (particularly focusing on tooling around geodata), and this should continue into 2025. The way we’re working at the moment is with longer meetings/workshops based around rich briefs: the client assembles their brief / queries as a team, I prep some responses, present back to them, and that opens up future discussion. It’s a nice shape of work, focusing on expertise rather than delivery, and makes a good balance with some of the more hands-on tasks I have going on.

Coming up

2025 is, currently, quiet; slightly deliberately so, but I’m eyeing up what’s next. I’m back teaching for a morning a week at CCI from mid-February; I have further brief consultancy with the games project on the slate; there are few other possibilities on the horizon. Plus, after a crunchy end-of-year on the delivery front, I’ve got a lot of admin to do, and ongoing personal research.

But that’s all “small stuff”.

Like clockwork, here is where I say “I’m always looking for what’s next”. You can email me if you have some ideas. Things I’m into: R&D, prototyping, zero-to-one, answering the question “what if”, interactions between hardware and software, making tools for others to use, applying mundane technology to interesting problems. Perhaps that’s a fit for your work. If so: get in touch.