Posts tagged as engineering

Process Notes: Jigs and Things

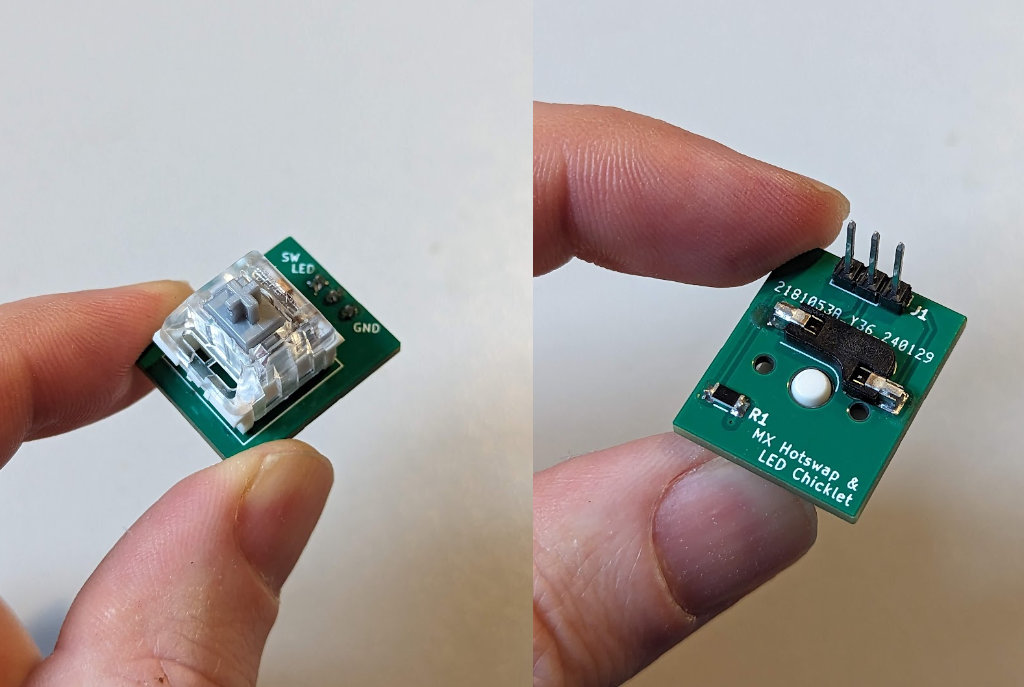

12 March 2024This is a recent prototype.

It’s a custom PCB that takes a single Cherry MX style keyswitch, with a resistor and an LED positioned to illuminate the keycap, broken out to pins. That’s it.

It’s part of a larger prototype, that involves buttons and controls and many chips. For a while now I’ve taken to prototyping quite large electronics projects in their full, final form. That means getting a large board made, fully populated with all parts, and then debugging it. It should work first time, but that’s not always the case, and a mistake can mean another costly revision.

This project has more unknowns in it than normal: new parts (like these keyswitches); new ICs; a UI that is still very much up in the air (and involves keys, knobs, and chording). So I’m prototyping it on a breadboard to begin with.

Breadboards often mean a lot of dangling jumper wires and bare components. But making small custom modules like the keyswitch module above can make your life a lot easier. In this case, ten small prototype boards to hold a single key were a few pounds in a recent larger order of PCBs. I’ve used hot-swap sockets so I can re-use the switches themselves in later work. The passive parts and pinheader cost pennies.

But: now I’ve got ten light-up mechanical keys to prototype with, and to reuse in later prototypes.

The keyswitch board is a particular kind of prototype that I build a lot, whether it’s in hardware or software: a small reusable atom, beyond bare wires, but not of use on its own. Crucially: it’s just for me. It might have utility to somebody else, but that’s by coincidence, not design. As a module, it’s not quite like the development boards in my prototyping drawer from firms like Adafruit and Sparkfun. It’s a more low-level building block.

I usually call these kind of things test harnesses or jigs. Here’s another jig, perhaps a more traditional use of the term:

This is a small 3D printed jig that assists me in placing an adhesive rubber foot in the correct spacing away from the corner of an object.

It took a few minutes to design - project the outline of the object, define an offset, extrude upwards, a quick subtraction - and about 15 minutes to print. It does one job, for one particular project, but it made positioning 28 rubber feet quick and repeatable.

Making a thing is usually about also making the tools to make a thing. Test suites; continuous integration; preview renders; alignment jigs. They’re as much part of the process as making the thing itself, and they are objects that show the growing understanding of the current act of making: you have understood the work well enough to know what tool you need next to make it; to know what tool you need next to think with. Making is thinking.

The switch jigs helped me understand how many buttons I’d need, what it’d be like if they could light up, whether it’d be useful to have a ‘partially lit’ state. They also helped me do this work without wasting money on permanently soldered switches. The foot jig came out of need: I had placed enough feet by hand to know that a more professional outcome could be achieved in half an hour of CAD and modelling, time that would be somewhat recovered by the quicker, more professional alignment process.

I love making tools. I particularly love making tools for other people to use and create with. But to only celebrate that kind of toolmaking obscures a more important kind: the ongoing, ephemeral toolmaking that is part of making anything. Making A Tool is not a ‘special’ act; people do it all the time. I think it’s important to celebrate the value of all the tools and jigs and harnesses that are essential to the things we make… and that also are inevitably thrown away or abandoned when the thing they enable comes into the world.

They’re process artefacts: important on the journey, irrelevant at the destination. I have drawers and project boxes and directories and repositories full of them, for all manner of projects - whether they are made of hardware, or software, or ideas, or words. They seemed like a good subject for some Process Notes.