Week 271

5 March 2018I spent a chunk of week 271 in the workshop.

The workshop is, of course, exactly the same as my desk (most of the time), but it’s being put to a different use. In this case, I continued to work on a few physical projects: either Foxfield-related electronics, or other physical objects related to music that I’m using to expand and develop skills.

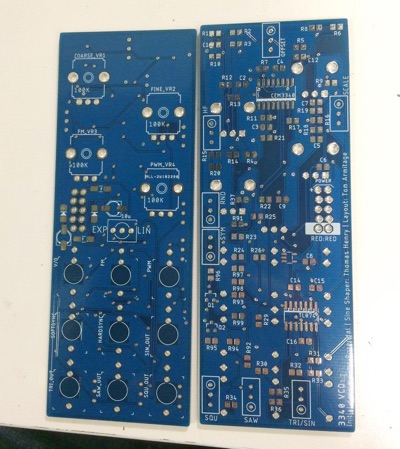

Electronics work included beginning to put together the pieces for a new run of kits for Thonk – acquiring parts from the UK, Europe, and China, and getting a few new PCBs and panels fabbed. Most of this will have arrived by the end of week 272, I think.

Some circuit boards for a personal project arrived, so I spent a few hours building a pair of those up:

These were my own variation on an original schematic by someone else, with a few new features added. Suitably interesting to layout, and I’ve definitely got a whole lot better at the schematic capture, layout and fabrication end of things. (They’re the second iteration on this board – though the first largely worked first time, this polishes it neatly and gives me some to donate to friends).

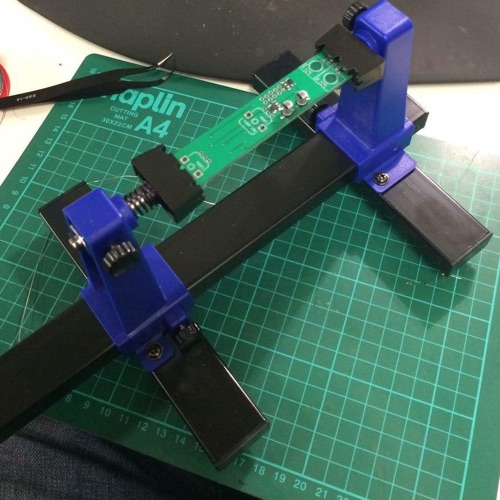

I also started work on what might be a prototype for a new Foxfield thing:

which went together very fast and, largely, functioned correctly. A few part-values need tweaking before I can confirm if it’s a GO or NO GO, though – but I can do this all on this board.

Another project I’ve got on the go is called 16n; it’s a musical controller made up of 16 faders, that emits data on a variety of channels – MIDI over USB and wire, I2C, and sixteen voltage outlets.

My work has mainly been the layout of all the electronics; collaborators have been working on the case and hardware. Whilst the electrics are feeling good, there’s still a little way to go with the hardware, so I’ve spent a period of time thinking about that this week. It’s a project that largely fits around other work – done as part of an online community – but it’s been enjoyable and I’ve learned a tone – easily the largest thing I’ve ever routed.

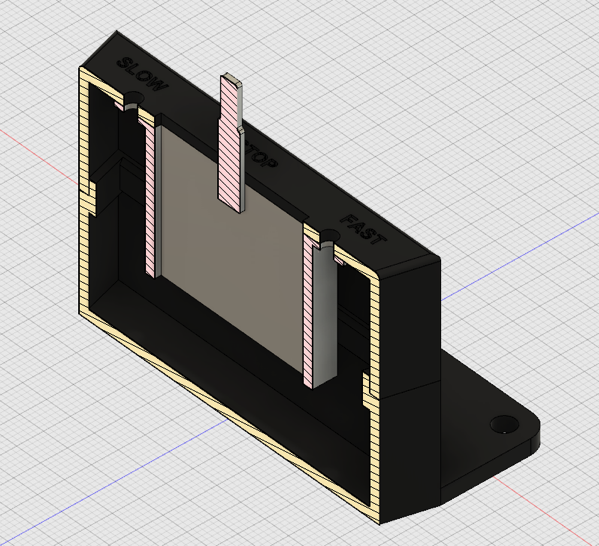

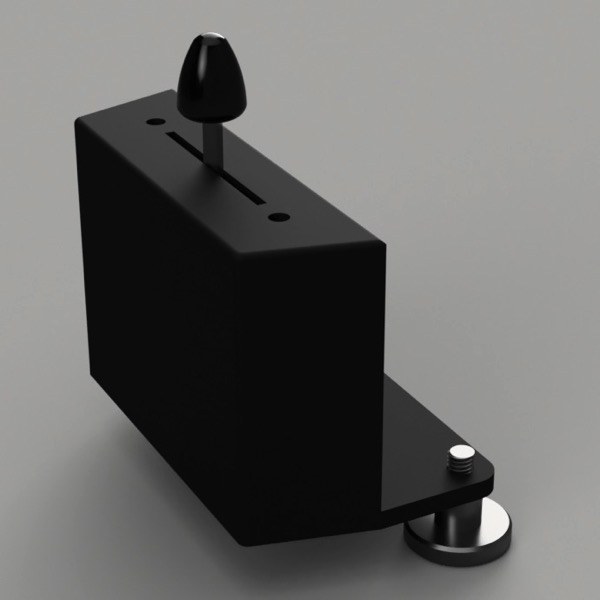

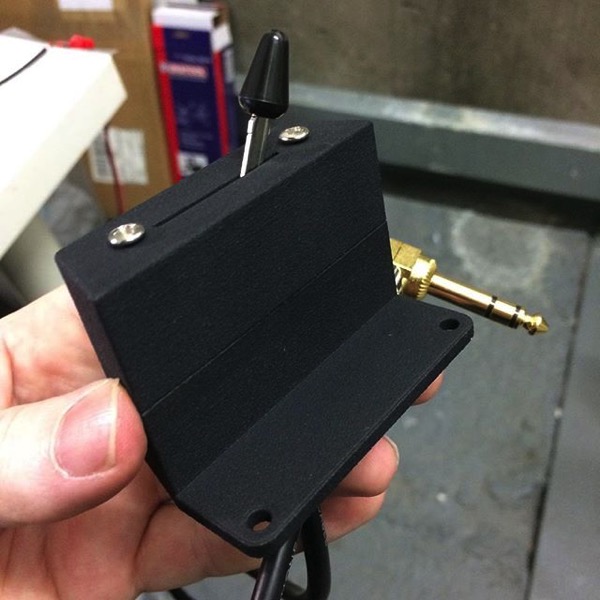

Finally, I also spent some time on building a half-moon switch for my electric piano/organ. The electrics on this project are simple – a flick-switch connected to three cores of a cable. The goal here, however, was to learn how to design a physical object in CAD for 3D printing. That meant modelling the switch, modelling a case around it correctly, adding features to the case so it would snap together, and making sure it fitted the organ.

The SLS-fabbed version arrived from Shapeways this week, and I put it together:

It works well… aside from the spacing of the two thumbscrews being incorrect, owing to an oversight on my part. And so I quickly knocked out a bracket to fix that issue, and ordered that.

Still: lots of progress on a few different projects, all functional, and all new muscles to exercise, even if all I’m putting it towards is being a somewhat mediocre engineer. But: new ways to think, that aren’t software, and are entirely absorbing whilst I’m working on them: I’ll take that, especially in this period of somewhat deliberate downtime.

I also spent a day on Selworthy, helping the team grapple with some subtitling formats for broadcasters, and the minutiae involved there. And, somewhere in the middle of this, there was a slow day at home in the snow.

A good week. Lots of hands-work.